Shipbuilding industry

THT Megaelement

THT Megaelement

A thousand mile embankment collapses in an ant colony. For ships that need to navigate continuously at sea for a long time, a minor equipment malfunction may cause a series of fatal problems, seriously threatening the safety of the ship and crew.

As the main equipment on the ship, such as lubricating oil cooler, fresh water cooler, central cooler, diesel engine cooler, cylinder liner water cooler, THT Juyuan's heat exchange equipment is widely used in oil tankers, liquefied gas ships, container ships, Bulk carrier and engineering ships, and plays an important role in the navigation process of ships. The highly corrosive and prone to scaling seawater operating conditions have tested the corrosion resistance and high performance of THT megaelement heat exchange equipment, and long-term continuous operation has tested the safety and stability of THT megaelement heat exchange equipment.

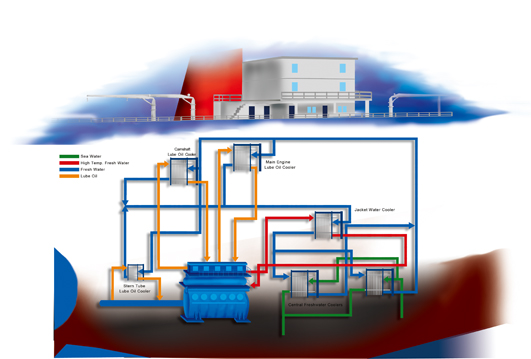

flow chart

Ship cooling water systems commonly include open seawater systems, closed freshwater cooling systems, and central cooling systems. The seawater and freshwater pipelines of the central cooling system are separated, with less corrosion and cleanliness in the freshwater pipelines, low management costs, and strong system reliability; High temperature and low temperature fresh water are used to cool different ship equipment separately, making the system highly adaptable and improving equipment performance.

The central cooling system is divided into high-temperature hot fresh water and low-temperature warm fresh water closed systems. The former is used to cool the main engine, while the latter is used to cool hot fresh water and various coolers. The heated warm fresh water is cooled by an open seawater system in a central cooler. Therefore, using only one cooler with seawater as the coolant simplifies the layout of the seawater piping system.

The vast majority of oil coolers are water-cooled, divided into three types according to different structural shapes: tube type, plate type, and spiral copper tube type.

中文

中文 English

English Россия

Россия