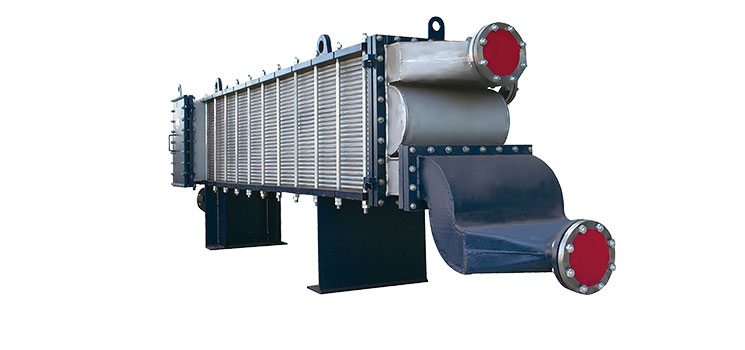

Fully welded wide channel plate heat exchanger

The fully welded wide channel plate heat exchanger is specially created for the special needs of customers. It is particularly suitable for treating media containing large amounts of solid particles, fiber suspensions, and viscous fluids in production processes in industries such as metallurgy, papermaking, sugar making, alcohol, chemical engineering, and sewage treatment.

1. Sheet forming

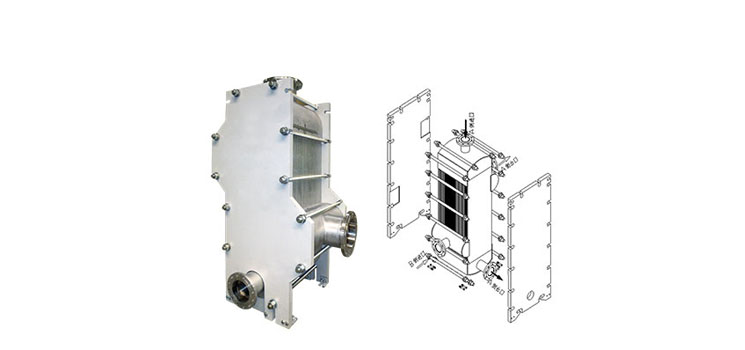

The fully welded wide channel plate heat exchanger has a large single plate size, with a maximum length of over 10000mm and a width of 1200mm. Using the technology of continuous pressing and forming of the entire plate in sections, a plate is divided into several parts and pressed in steps on a ten thousand ton hydraulic press, ultimately completing the forming of the entire plate. The length and structural dimensions of each section of the pressed plate are completely consistent. This forming method is developed on the basis of traditional plate heat exchanger plate forming technology, ensuring the assembly and welding quality of plate pairs.

2. Plate inspection

In order to ensure the manufacturing quality of the plates, in accordance with the national standards for plate heat exchangers and based on the special requirements of fully welded wide channel plate heat exchangers, plate inspection specifications have been specially formulated.

3. Welding method

The plate spacing column plate welding adopts laser welding. The weld track is round and the weld width is narrow. Then, seam welding is used to weld the longitudinal long welds on both sides of the plate, and automatic argon arc welding is used for the outer end welds.

Laser welding technology ensures the superior quality of the equipment, fully adapting to various temperature and pressure harsh working conditions, and avoiding quality issues such as shutdown and leakage.

To ensure the safety of welding quality, non-destructive testing and hydraulic pressure testing are conducted on the plate after welding is completed to verify the feasibility of welding process and design calculation strength.

4. After each plate pair is welded, a 0.6-0.7MPa airtightness test is conducted to ensure the sealing of the individual plate pairs.

Advanced processing technology has achieved product quality, and excellent quality will enable equipment to better serve customers' process systems for a long and safe time.

中文

中文 English

English Россия

Россия