petrochemical industry

THT Megaelement

THT Megaelement

Chemical technology and petrochemical industry have always been the main driving forces for the progress of human civilization, enabling sustainable development and improvement of human civilization and life. In the early 20th century, as crude oil and natural gas were gradually used as the main raw materials for the production of chemical products, petrochemical industry, as the most basic industry, has always received high attention and played an increasingly important role on the world economic stage.

With the rapid development of modern chemical industry, THT Giant has also gone through more than 30 years. From providing the first plate heat exchanger for the chemical industry in 1986, to today, it has provided more than 20000 sets of various heat exchangers to many users' process installations, including BP, LG, DOW, SHELL, BASF, Sinopec, and PetroChina. More than 80% of them are compact heat exchangers mainly based on plate heat transfer products, accumulating rich experience.

From the initial simple provision of products to gradually conducting system analysis and optimization, THT Megaelement knows how different products can play a greater role in the process system, how to shorten installation and downtime, how to improve unit efficiency, how to reduce operation and maintenance costs, how to reduce installation space, and so on. With scientific system analysis and design, THT Megaelement can provide services to users on a wider range. THT Megaelement aims to meet users' comprehensive requirements for equipment safety, economy, and lifespan, providing system solutions to users, with results that greatly exceed expectations.

sulphuric acid

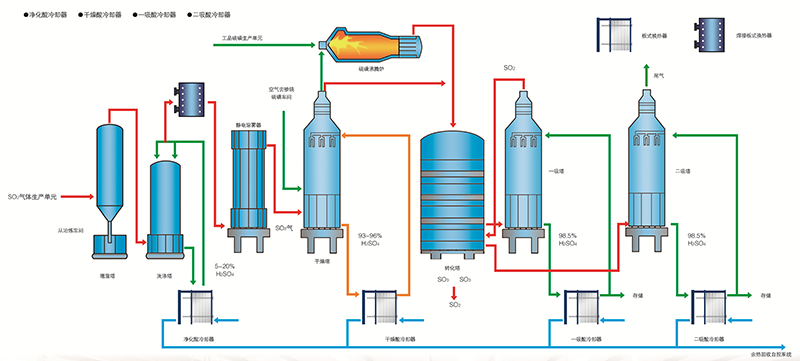

In the smelting and acid making process, there are generally purification acid coolers, drying acid coolers, first suction acid coolers, and second suction acid coolers. The purified acid cooler is mainly used for reducing the temperature of dilute acid, and the medium is generally dilute sulfuric acid and water with a concentration of about 5-20%. The medium for the dry acid cooler is sulfuric acid and water with a concentration of 93-96%. The medium for the first and second suction acid coolers is concentrated sulfuric acid and water with a concentration of about 98.5%.

在硫酸生产中的工艺流程

烧碱

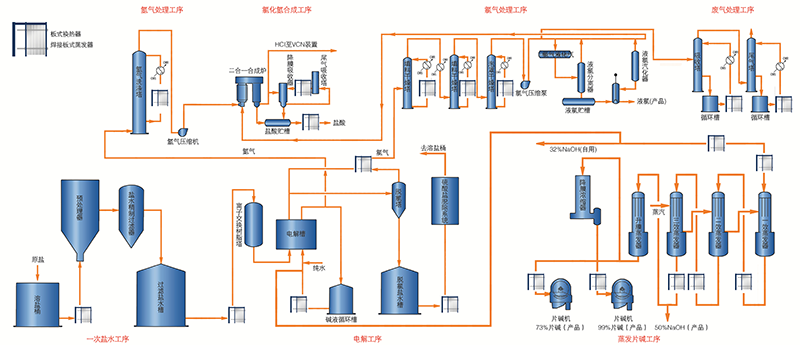

Process flow in caustic soda production

Primary brine process:

The raw salt enters the salt tank and is dissolved with the dilute brine from the electrolysis process, the recovered water from the device, and the supplementary water to obtain saturated coarse brine.

Electrolysis process:

The electrolysis process includes three parts: secondary brine refining, electrolysis, and dechlorination of dilute brine.

Evaporation solid alkali process:

The 32% NaOH obtained from the electrolysis process is evaporated through a three effect countercurrent falling film evaporation process, resulting in a NaOH concentration of 50% in the alkaline solution. It is then sent to the concentration unit to produce flake alkali and granular alkali.

Chlorine treatment process:

The wet chlorine gas from the electrolysis process is first washed by the chlorine washing tower, then enters the chlorine cooler for cooling with chilled water. It is then sent to the packing tower through a water mist separator for countercurrent contact with sulfuric acid for the first step of dehydration. The chlorine gas from the packing tower is then sent to the bubble cap tower for countercurrent contact with concentrated sulfuric acid for further dehydration. The acid mist is then captured by the acid mist collector, and then compressed and pressurized by the chlorine compressor before being sent to the chlorine gas user.

Waste gas treatment process:

During the start-up, shutdown, and accident states of the device, the chlorine gas is first absorbed in the absorption tower with the absorption alkali solution from the circulating tank. The tail gas after the absorption reaction enters the tail gas tower for further absorption with the alkali solution. At the same time, the absorption liquid is made into 10% NaClO product and sent to the acetylene device.

Hydrogen treatment process:

The wet hydrogen gas from the electrolysis process, with a temperature of about 85 ℃, enters the lower part of the hydrogen washing tower and is directly cooled and washed with the circulating liquid sprayed inside the tower. The alkali mist and steam condensate contained in the hydrogen gas are taken away by the circulating liquid, and then sent to the hydrogen compressor for pressurization. After two stages of cooling, it is sent out of the battery limit.

Hydrogen chloride synthesis and high-purity hydrochloric acid process:

Chlorine and hydrogen gas are burned in a two in one graphite synthesis furnace to generate hydrogen chloride gas. The generated hydrogen chloride gas is cooled by the hydrogen chloride cooling water tank and hydrogen chloride cooler, and then partially sent to the VCM device as raw material through the hydrogen chloride distribution platform, and partially sent to the high-purity hydrochloric acid absorption system.

coking

The main production workshops of the coking plant include: coal preparation workshop, coking workshop, gas purification workshop, and public and auxiliary facility workshop. When coal is coking, in addition to about 75% becoming coke, there is also about 25% generating various chemical products and gas. Recycling coking chemical products is of great significance. The chemical recovery process is the rational and effective utilization of various chemical products generated in coking. The raw gas generated in the coking room of the coke oven is cooled, transported and recovered from coal tar, ammonia, sulfur, benzene hydrocarbon and other chemical products in the chemical product recovery workshop, and the gas is purified at the same time. The gas purification workshop consists of a condensing and blowing section, a desulfurization section, a ammonium sulfate section, a final cold benzene washing section, and a crude benzene distillation section.

Plate and frame heat exchangers are usually used in the lean and rich oil heat exchangers, lean oil first stage coolers, and lean oil second stage coolers of the crude benzene distillation section in the coking industry. Their following characteristics meet the operational requirements of this section and are very ideal heat exchange products.

1. The plate and frame heat exchanger has the characteristics of high Heat transfer coefficient and low pressure drop.

2. Strong adaptability to working conditions, plate and frame heat exchangers can flexibly set process combinations according to different process requirements.

3. Compared with spiral plate heat exchangers, it has better cleaning performance. During cleaning, the heat exchanger can be directly removed from the side plate on the production line and then purged with 0.4Mpa steam. If conditions permit, the side plate can also be directly removed for cleaning on the production line.

4. Strong temperature and pressure resistance, suitable for special media. Compared with detachable plate heat exchangers, the use of welding structure eliminates the impact and corrosion of high temperature and special medium conditions on the sealing gasket, and improves the ability to use temperature, pressure, and adapt to the medium.

中文

中文 English

English Россия

Россия