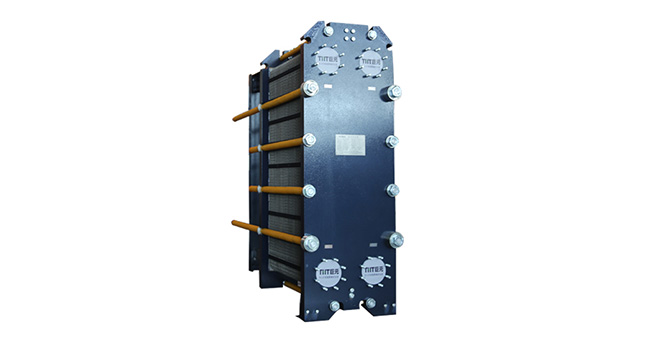

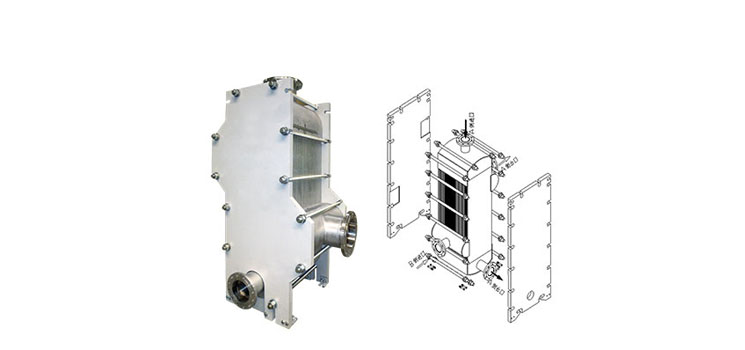

Semi-welded plate heat exchanger

1. The international advanced laser welding machine (Optical fiber laser generator) and modern laser welding technology are used for welding. A major scientific and technological research project in Jilin Province, which won the second prize for scientific and technological progress in Jilin Province, carried out welding process research and development together with Jilin University. Compared with other welding methods, laser welding adopts single weld process, which has advantages of small heat affected zone, small deformation after welding, high welding quality (automatic detection during welding), fast welding speed, small residual stress ratio, etc.

2. The combination of advanced international welding technology and a large number of practical application cases in China has created a brand of semi welded plate heat exchangers. And has obtained the B2-- B3 level safety registration certification for national welded plate heat exchangers.

3. Welding of plate pairs

THT Giant adopts a template positioning system. Firstly, CNC spot welding machines are used for spot welding of the support points of the pits and valleys. Then, CNC seam welding machines are used to weld the longitudinal pairs of plates formed by the spot welding. Each pair of plates is welded with guide plates, which can ensure the welding quality of the plates at the starting and ending ends. Additionally, mechanical performance tests can be conducted on each guide plate to verify the welding quality of the plate pairs, Thus fully ensuring the pressure bearing capacity and safety performance of the semi welded plate heat exchanger.

The main equipment is industry-renowned equipment, and many products and technologies are kept confidential.

中文

中文 English

English Россия

Россия