food processing

THT Megaelement

THT Megaelement

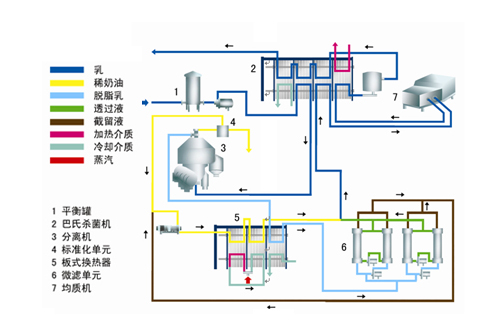

Pasteurization is mainly a sterilization method used in milk processing, which can kill pathogenic bacteria harmful to health and minimize changes in milk quality. This is a method of heating at low temperature for a long time or at high temperature for a short period of time, based on the principle of the difference between the heat death curve of highly heat-resistant tuberculosis bacteria and the heat damage curve of the most susceptible butter in milk. The method of heating below 60 ℃ for 30 minutes has long been widely adopted worldwide as a standard for low-temperature sterilization. The use of high-temperature treatment (heating above 95 ℃ for 20 minutes) may have some impact on the quality of milk, but it can enhance the sterilization effect. This method is called high-temperature sterilization.

Plate type pasteurization equipment is mainly used for continuous sterilization of fresh milk, fruit juice, beer, beverages, or similar products. It can be connected to equipment such as centrifuges, degassers, flash evaporation, etc. The equipment is mainly regulated by a flow controller in the feeding system, and the flow is controlled by a full flow homogenizer. Due to the heating and cooling of the product being carried out in the heat recovery section of the plate heat exchanger, the maximum heat recovery rate can reach over 94%.

中文

中文 English

English Россия

Россия