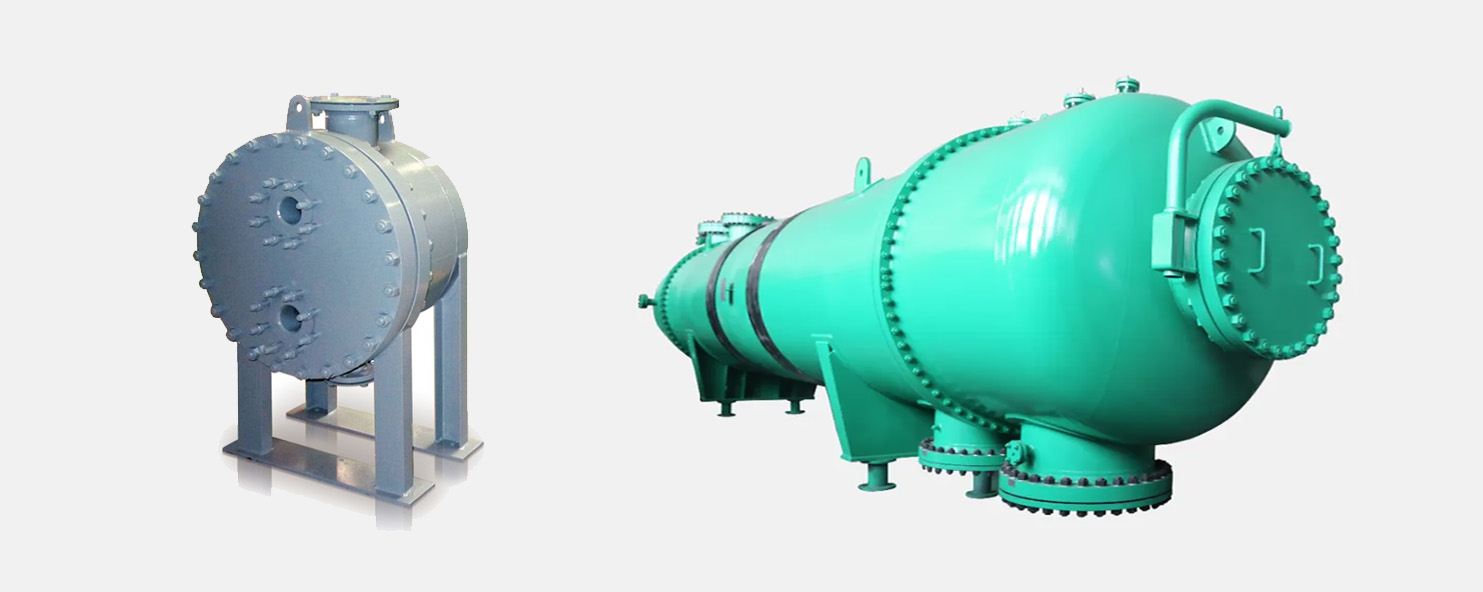

Plate (tube) shell heat exchanger

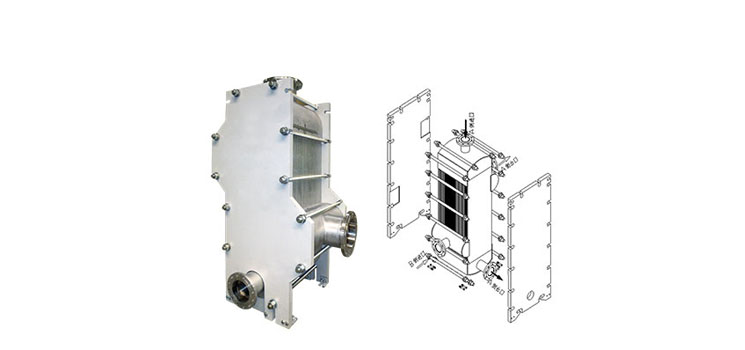

1. Plate structure form

Plate is the core component of plate shell heat exchanger, and its structural form directly affects the determination of plate manufacturing technology and process, and affects the effectiveness of plate shell heat exchanger. The main forms of plates for THT giant element welding equipment include chocolate shaped ripple structure, horizontal ripple, oblique ripple, and herringbone ripple, and different structural forms are suitable for different working conditions.

2. Sheet forming

The plates are formed using a single process of overall pressing, with the length and ripple size of the pressed plates being completely consistent. At the same time, after the plates are formed, a laser cutting machine is used to align the edges around them, ensuring the same size of each plate and ensuring the quality of plate pairing and welding.

3. Plate inspection

In order to ensure the manufacturing quality of plates, in accordance with the national standards for plate heat exchangers and based on the special requirements of plate and shell heat exchangers, a plate inspection specification for plate and shell heat exchangers has been specially formulated.

THT Giant has developed mature product manufacturing and inspection procedures through various forms of welding tests and evaluations, as well as years of experience in manufacturing special material products; And after the overall welding of each pair of single plate tubes and plate bundles is completed, an air tightness test of 0.6-0.7MPa should be conducted to ensure the overall sealing of the plate tubes and plate bundles.

Welding technology, heat transfer technology design, and intelligent process processing technology guarantee the value and quality of THT giant element tube (plate) heat exchanger; Part of the shell type equipment can withstand an operating pressure of 6.0MPa. And it has been specifically applied in important national heavy equipment projects such as nuclear power and military industry.

中文

中文 English

English Россия

Россия