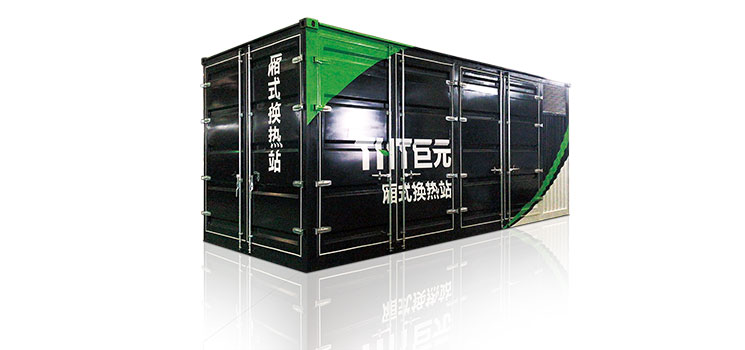

Standardized heat exchange unit

1. Professional design: We provide customers with a selection plan of 10000 units per year, as well as successful application cases of 1500 heat exchange units, which are higher than the national standard of THT Giant Element. Configuration standardization and structure standardization: Based on our company's years of practice, we have refined high-quality and cost-effective configurations and structures.

Standardized configuration accessory brands are all THT Juyuan strategic cooperative brands. After years of practical application testing, they adopt THT Juyuan standards, ensuring quality, performance, and high cost-effectiveness.

Structure standardization: according to THT's giant Big data analysis and years of design and operation experience, the unit structure is standardized designed to achieve standardized and modular production. Improve quality and shorten delivery time.

Standardization of control programs: strong component compatibility, complete functionality, and stable operation; The operation interface is unified and embedded with common fault diagnosis guidelines, making it easy to operate. Energy consumption analysis function: analyze the energy-saving operation of the unit in real-time based on the power consumption heat transfer ratio, heat consumption per unit, electricity consumption per unit, and water consumption per unit;

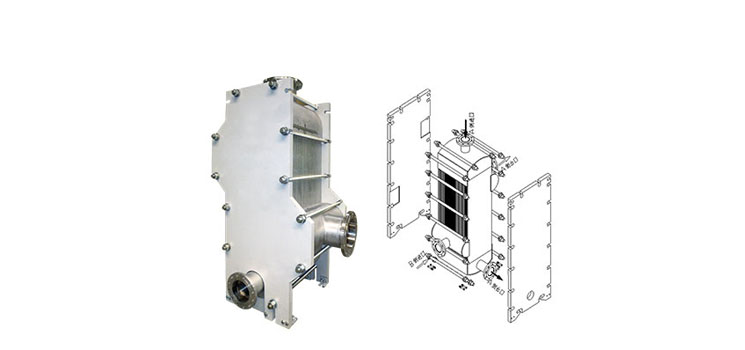

Comparison of standardized unit technical performance with national standards: board exchange pressure drop THT giant element standard 40KPa @ national standard 50 KPa, unit pressure drop primary side THT giant element standard 60KPa @ national standard 100 KPa, secondary side THT giant element standard 80KPa @ national standard 100 KPa. THT Giant Element Standard Energy Efficiency Analysis @ No requirements in national standards.

2. Precision manufacturing: standardized and modular assembly production. Automatic sizing and cutting (cutting accuracy), automatic assembly, intelligent welding (corrosion resistant and leak free), sandblasting and rust removal, electrostatic spraying, module assembly, pressure debugging, and factory inspection.

3. Quick installation and easy operation: directly start after taking over power, standardized program, no need for on-site debugging.

4. Intelligent and efficient: unmanned, energy efficiency analysis.

5. Enjoy service: The responsible party is clear, one-stop service, and arrive at the site within 12 hours. Provide services in 4S mode.

1S: Product Services

① Whole machine sales.

② Spare parts supply: equipment accessories and components (other manufacturers' products adopt the THT giant yuan supervision mode.)

2S: After sales service

Installation guidance, operation training, maintenance tips, maintenance, fault diagnosis, fault handling, technical consultation.

3S: Engineering Services

① Heat exchange station general contractor

② Upgrading and renovation of heat exchange system

③ Smart heating platform and industrial control platform

④ Maintenance and cleaning items

4S: Technical Services

① Technical consulting and management consulting

② Energy efficiency analysis and solutions

Provide customers with high-quality and cost-effective products and services!

中文

中文 English

English Россия

Россия