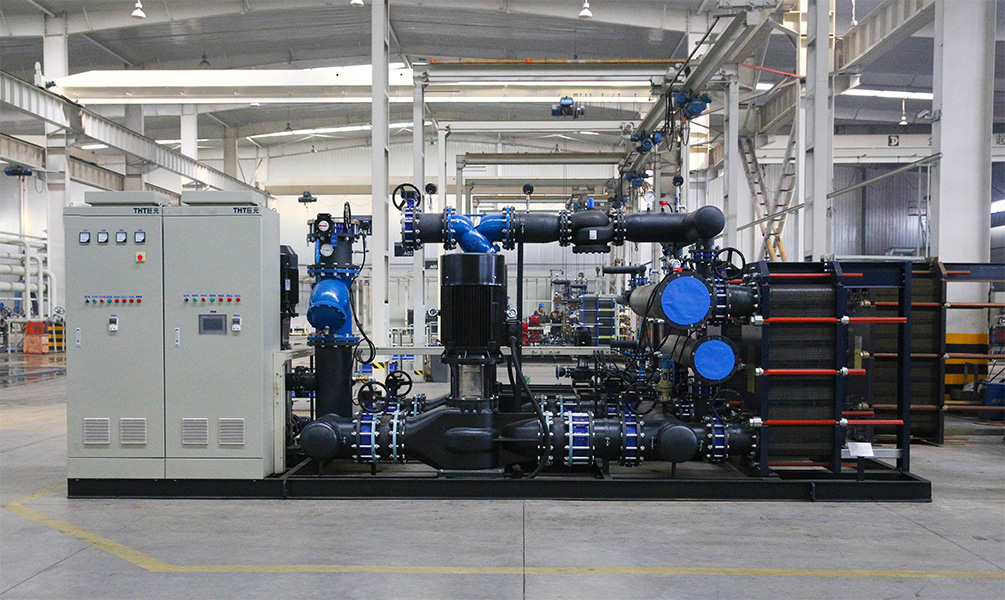

Integrated heat exchange products

THT Megaelement

THT Megaelement

Central heating is an important symbol of urban modernization, an important measure to save energy and improve the environment. With the continuous development of heating industry, users have put forward higher requirements for the stability and quality of heating. The plate heat exchange unit is the main body of the heat exchange station, and the THT Juyuan series plate heat exchange unit is developed based on the characteristics of centralized heating. It has good environmental performance, and the overall operating noise of the unit is less than 70db. The structure is compact, the appearance is beautiful, the operation is simple, and it is safe and reliable.

THT Juyuan series plate heat exchanger unit is a complete set of district heat supply control equipment integrating plate heat exchanger, circulating pump, make-up pump, thermometer, pressure gauge, various sensors, pipelines and valves and industrial control, and is additionally equipped with water make-up system, pressure stabilizing system, frequency conversion flow control system, heat metering and network communication control system. At the forefront of industry technology, THT Juyuan Station combines the on-site selection of water pumps, valves, and electrical control debugging work of a large number of users with THT Juyuan's advanced technology, rich experience, and standardized module design. In the selection of unit accessories, such as water pumps, valves, and industrial control, THT Juyuan takes into account all aspects, tailoring complete heat exchange units that are more suitable for user conditions and have excellent performance for users. Including industrial control, the entire unit leaves the factory, and users only need to install five pipelines and one power cord on site to the electric control box of the unit to debug and operate the unit.

operational principle

Plate heat exchange units automatically and continuously convert the heat obtained from the primary network into the domestic water and heating water required by users. That is, hot water (or steam) enters the plate heat exchanger from the primary side inlet of the unit for heat exchange, and then flows out from the primary side outlet of the unit; After removing dirt through the filter, the secondary side return water enters the plate heat exchanger through the secondary side circulating water pump for heat exchange, producing hot water at different temperatures for heating, air conditioning, or floor heating to meet the needs of users.

THT Giant Element Heat Exchanger Unit Function (selectable according to user needs)

1. Temperature regulation control: The circulating water flow remains unchanged, and the heating temperature is automatically adjusted according to changes in environmental temperature to match the heating volume with the system load, achieving the goal of saving heat energy.

2. Flow regulation control: The heating temperature remains unchanged, and the circulating water flow is automatically adjusted according to the changes in environmental temperature and the difference in supply and return water pressure, in order to match the heating amount with the system load and achieve the goal of saving electricity.

3. Water supply pressure control: Based on the measured system pressure, the pressure sensor automatically starts and stops the water supply pump or adjusts the speed of the water supply pump to stabilize the system pressure, ensuring thermal safety and maintaining normal system operation. The pressure control range is determined according to the design requirements.

4. Condensate recovery control: The condensate pump is automatically turned on and off by the liquid level controller based on changes in the water tank level, and the condensate is automatically sent back to the boiler room for recycling, reducing the waste of softened water and heat. The control range of the condensate water level has been determined at the factory.

Characteristics of THT Giant Element Heat Exchange Unit

1. Intelligent control, complete control functions, high control accuracy, and stable and reliable operation.

2. The unit adjusts the heat source and hot water supply based on parameters such as environmental temperature, primary and secondary pipe network temperature, pressure, etc., which has a significant saving effect on thermal and electrical energy during system operation.

3. The system components have high reliability, and the heat exchanger is a THT giant element high-efficiency plate heat exchanger. The main intelligent components are imported, ensuring stable and reliable operation and durability.

4. The system automatically controls pressure, temperature, or flow rate, which is intelligent, highly automated, and easy to operate.

5. It can be remotely monitored and can also switch between manual and automatic modes.

6. Unmanned duty units can also achieve remote direct monitoring without the need for duty personnel on site.

7. The unit layout is reasonable, the structure is compact, the floor area is small, the infrastructure investment is saved, the installation and maintenance are convenient, and it is suitable for various heating occasions and heating requirements.

中文

中文 English

English Россия

Россия